The Timber Pond in Pembroke Dockyard

In the age of wooden ships, naval dockyards (and civilian shipbuilders) used copious amounts of timber. The seasoning of timbers was an important aspect of ship construction if the constructor did not want the vessel to warp and bend unpredictably. Also, there was a need to intentionally bend and shape timbers and it was found that soaking in water made the bending of timbers easier.

By the middle of the nineteenth century it had been found that soaking timbers in salt water before working them allowed suppling or bending to be more easily performed. Also, the salt that impregnated the timber helped in its preservation, particularly if the timber was "in the log".

Originally the timber was stored in a timber pond that was on the foreshore at the the western end of the dockyard, on the beach at the end of what is now Fort Road. Indeed, the stumps of some of the timber piles that penned in the timbers can sometimes be seen during spring tides.

|

| Notice the poles of the old timber pond on the beach at the end of Fort Road c1890 |

The diagrams below shows the basic design of the timber pond (Listed Grade II), taken from a the plan of the design held at The National Archives at Kew, London.(TNA Ref: WO 140/486).

|

| Timber Pond with Google Earth Imagery |

|

| As above but with some transparency |

|

| The Timber Pond |

The timber pond at Pembroke Dockyard, (also called the mast pond or pickling pond), is one of the few (perhaps the only?) masonry built example surviving in the British Isles. The quality of the stone work is of its time, crafted in individually cut, carboniferous limestone blocks. Fairly recent inspection reports reveal that the pond is in good condition. It has two large, brick lined, tunnel conduits running into it from the outside world. One of these, in the western wall of the pond, runs to an outfall on the beach at the end of Fort Road. This has a system of sluices and flap seals that can be used to drain and seal the pond as required. The other conduit runs from the north wall of the pond to the southern end of the graving dock, and was (probably?) used to fill the pond with water from the dock.

The diagram below shows this general arrangement of the Western Part of the dockyard. The numbers against some of the older buildings were allocated as part of a separate project to commemorate the Bicentennial of Pembroke Dock in 2014. They were for project identification purposes only.

Some people reading this post may not even be aware of the existing of the Timber Pond, which is hardly surprising, as unless you have access to the western part of the dockyard, it is hidden behind the impressive dockyard wall. Its relative anonymity does not make it any less important in its significance to the heritage of ship building at Pembroke Dock, and indeed Wales and probably the wider UK.

|

| The timber pond c1890 |

|

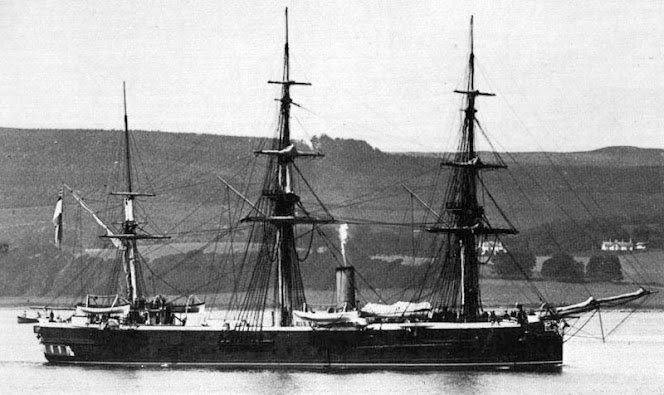

| HMS Penelope. Launched Pembroke Dock 1867 |

|

| HMS Shannon. Launched Pembroke Dock 1875. |

The Milford Haven Port Authority (MHPA) proposes to fill in the pond and cover it with a concrete slab as part of a speculative plan to make Pembroke (Dock) Marine a home for marine energy development. MHPA proposes to the fill the pond in so that damage to the structure is minimal, however, removing the concrete slab and extracting the fill would be a massively expensively task for anyone wishing to uncover the pond in the future. The pond is being effectively destroyed.

|

| View across the drained timber pond from the southern edge looking north-west. 2014 |

|

| Looking across the pond form the southern edge looking north-east. Not the conduit that leads to the dry dock. This is the block oval near the ramp in the northern wall. 2014 |

|

| The timber pond in an old photograph, taken for the east. The other buildings visible have been demolished. c1970? |

Working in the dockyard and next to the graving dock for over thirty years. I thought about the conduit at the north end of the pickling pond and came to the conclusion that you fill the pond on a spring tide, then you send it through the culvert to the graving dock when you want to undock a ship. Using the water to equalise the pressure in the dock to the same as outside the dock. Allowing you to move the caisson and open the dock

ReplyDelete